WhatsApp)

WhatsApp)

such mills could grind down to the ultra fine sizes required for mineral liberation. Arising from these findings, ... overgrinding and the creation of ultra fines.

The IsaMill is a stirredmedium grinding mill, ... It also means that there is less overgrinding at the finer end of the size distribution, ...

Large screens on small footprint raise production and lead recovery ... began with three parallel rod mills ... and overgrinding of the high

Usually the AG/SAG mill works in closed circuit with a vibrating screen, ... immediate recovery without loading up the mill and minimizing overgrinding.

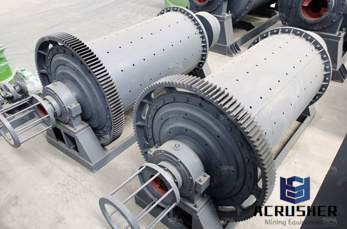

HighEfficiency Roller Mills the Industrial Efficiency Technology . Ball mills use an established technology and offer certain advantages. ball mills are used in ...

improving energy efficiency via optimized charge motion and slurry flow in plant scale sag mills. final technical report raj k rajamani, project manager

a grinding process in which large pieces of the material to be ground—ores and rocksserve as the grinding medium; the process is carried out in drum mills.

Original document English (PDF 786kb) . as the optimisation of the SAG mills lifter/liner design, pulp lifters, ball ... costs, and to reduce overgrinding ...

SemiAutogenous Grinding (SAG) mill, ball mill, grinding circuit, ... Correct operation of this section is vital to reduce overgrinding and its effect not ...

In modern grinding, ball mills and SAG mills are two types of mill commonly found. Grinding mills Ball mills ... reduce overgrinding, improve product

AG/SAG mills can handle feed ore as large ... This decreases overgrinding and increases the energy available for useful grinding as long as there is an ample ...

On Sep 1, 2015 L. Liu (and others) published: Grinding technical efficiencies in various comminution modes

Energy Use of Fine Grinding in Mineral Processing ... AG or SAG mill, ... will result in overgrinding of fines as well as high media

Figure 2 shows SAG and ball mills breakage rates. ... The strategy here was to reduce Ni mineral overgrinding and therefore the Ni losses in flotation.

The circulating load is about 350% and overgrinding of the ... Outokumpu Technology, looks at the shift from ball mills to SAG mills. ...

* overgrinding is to be minimized ... SAG mills operate with big rocks of the ore itself plus steel balls to improve efficiency.

2001 1 ag sag mills_[PDF]2001 1 AG SAG Mills Bulgaria metsobulgaria files smilane Broshura_AG_SAG pdfApplication AG SAG mills are normally used to grind ...

The IsaMill is an energyefficient ... a German manufacturer of bead mills. The IsaMill is primarily ... It also means that there is less overgrinding at the ...

grinding mills. Grinding mills supplied by FL have their origins dating back to the Fuller Company, based in Bethlehem, ... number of SAG Mills have been

Jacking Sag Mill For. ... aspect AG and SAG mills to suit any application across ... Overgrinding In Sag Mills;

CHAPTER 1 INTRODUCTION ... the recirculating load as well as overgrinding. Galan et al. (2002) presented two H ... (SAG) mill. A typical mill has

2. SAG Mills Download as Powerpoint Presentation (.ppt / .pptx), PDF File (.pdf), Text File (.txt) or view presentation slides online. sag mill

SAG mills can have diameters up to 13 ... SAG MILL Output: Mill Filling: Overgrinding Low Charge The falling rocks smash against the ...

Model Predictive Control of SAG Mills and ... Correct operation of this section is vital to reduce overgrinding and its effect not onlyassisted grinding is known as ...

WhatsApp)

WhatsApp)