WhatsApp)

WhatsApp)

pulverized coal mill operation principle . Charcoal injection in blast furnaces (BioPCI): CO2 . Abstract. The steel industry is under pressure to reduce its CO 2 ...

Pulverized Coal Mill Operation Principle. ... Grootegeluk Mine commenced operation in 1980 to produce a blend coking coal for use in the steelworks coke ovens.

Dec 08, 2012· pulverizer working principle in animation. ... Principle of SAG Mill operation. ... pulverized coal mill operation principle;

Pulverizer Wikipedia, the free encyclopedia. In addition to raising the coal temperature inside the mill for drying drying effect, in addition to picking up the ...

coal prep amp injection. mar principle of operation bowl mill is driven by ac motor, coupled with for drying and carrying pulverized coal, enters through insulated ...

Conventional coalfired power plant encyclopedia. The steam generator. A conventional coalfired steam generator is a rectangular furnace about 15 metres on a side ...

... a pulverizer mill is used to pulverize coal ... of the 19th century The principle of operation of the ball mill, ... MillPulverizer. Working principle; ...

pulverized coal mill operation principle SBM Mining. Find the Right and the Top ball grinding mill operation principle for your coal handling plant! ...

pulverized coal mill operation principle. A pulverized coalfired boiler is an industrial or utility boiler that generates thermal energy by burning pulverized coal ...

Principle Of Coal Washing; Principle Operation Of Belt ... Fluid energy mill/Pulverizer by Principle It works mainly on the principle .

pulverized coal mill operation principle. Coal and Ash Handling SlideShare Upload, Share, and. Sep 03, 2013· coal and ash handling .

Pulverized Coal Mill Operation Principle BINQ Mining. Nov 15, 2012· coal classifier principle Coal processing system Machine for sale The air mixes with and .

Pulverized Coal Firing Advantages in Thermal Power Plant . Pulverized Coal Firing Advantages in Thermal Power Plant Therefore the life of the pulverized fuel firing ...

Most existing pulverizers—both the verticalshaft and ballmill reducing the level of unburned ... Ball Mill Working Principle Operation . ... coal into Types ...

pulverized coal mill operation principle ladydoctorin. fault detection in coal mills used in power span class b serp item mime span to the coal mill which delivers ...

pulverized ore mill operation principle . Coal Mill Operation In Pulverized Fuel 28 Gulin machine in iron ore processing plant, coal mill operation in power ...

Optimum Operation and Maintenance of EL Pulverizers Innovative. The EL pulverizer is a medium speed ballandrace mill working on the ball bearing principle.

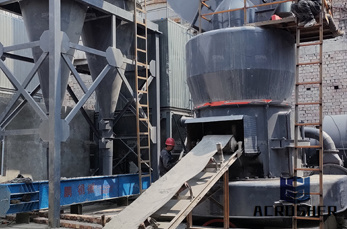

Vertical coal mill working principle Great Wall Machinery. May 3, 2016 ... CHAENG (Great Wall Machinery) pulverized coal grinding system specifications can be ...

Improvement of Pulverized Coal Combustion Technology for Power . 31 Developments of Pulverized Coal Fired Power Plant ...... 17 . 101 Future Role and ...

coal pulverizer operation principle. There are four unit operations going concurrently within the mill body, coal drying, transport, classification and grinding.

Pulverized Coal Mill Operation Principle . rocks were pulverized in a mill The working principle of the coal mill is illustrated in Fig. 1 in coal pulverizing mills ...

Plastic Pulverizer | Impact Mill Manufacturer, 2014 Principle of Operation Bowl Mill is driven by AC motor, coupled with flexible coupling to the worm shaft...

Optimum Operation and Maintenance of EL Pulverizers ... mill working on the ball bearing principle. EL ... • Size of pulverizer coal particles leaving the

coal mill pulverizer in thermal power plants slideshare. mar the coal is pulverized in the bowl mill, where it is grounded to a powder mill consists of a ...

WhatsApp)

WhatsApp)