WhatsApp)

WhatsApp)

The ball mill is used for grinding ... An internal cascading effect ... enormously increasing surface area and reaction rates. The grinding works on the ...

Ball Rolling Mills For Steel Grinding ... but does not use steel balls in the mill. . grinding balls to aid in grinding ... Wear Rate Hot Rolling Forging ...

Internal inspection of the mill can reveal a lot of important and ... Use of suitable grinding aids also is recommended ... and wear rate of grinding media ...

FL ball mill for cement grinding. ... rates and moist mill feed. An internal water cooling system may ... the mill is a highly wearresistant step

This type of mill consists of a rotating tube ... Fine coal particles and wear metals from grinding surfaces enter the lube ... inherently high ingression rate.

ATTRITOR GRINDING MILLS AND NEW DEVELOPMENTS ... is a grinding mill containing ... The material is charged into the mill at the top by a preset rate ...

It is wellknown that lab tests on wearrate of grinding media ... are in vertical stirred mill for media A and B, only the wearrate ... sintering aids are needed in ...

be applied in cement grinding ... the feed are "additives" which includes grinding aids. ... particles inside the mill (tonnes) di the discharge rate of ...

Effect of grinding aids on the timeflow characteristics of the ground product from a batch ball mill

Lower wear rate of mill liners and grinding media. ... Mill HP is proportional to the power* of the internal mill ... Grinding Mill Feed Chutes. Grinding mills ...

ultrafine grinding, new comminution technology ... to achieve lower consumption rate and higher grinding ... a longer lasting life to the internal mill wear ...

Dec 15, 2011· Shaping Internal splines with mill good ... bearings to wear (or fail) at a faster rate. ... keys and internal and external splines using a hss tool ground to ...

Mathematical model of ball wear in grinding mills I. Zeroorder wear rate. ... of Ball Wear in Grinding ... mill, we will consider only one internal co ...

Fine grinding using stirred mills and ceramic beads is ... internal wear and ... Abrasion test where Bond developed correlations giving wear rate in lb of ...

Safety steps for proper use of grinding wheels ... Internal grinding requires the grinding wheel ... corner wear The tendency of a grinding wheel to wear on its

OK™ cement mill. 2 ... Optimal wearprotection on all internal surfaces ... rotor speed, the mill airflow rate and the grinding pressure, ...

Three types of feeder are in use in wetgrinding mills. ... but utilizes grinding balls to aid grinding ... SemiAutogenous Grinding Mill; VERTIMILL Grinding ...

FINE GRINDING IN THE AUSTRALIAN MINING INDUSTRY ... and resultant grinding action within the mill are the ... that the greatest wear rates occur at the bottom ...

... vibration in the mill mill, serious wear of grinding roller ... The penetration rate of this technology in ... the need to use water and grinding aids ...

CEMENT ADDITIVES POWERFUL GRINDING AIDS. ... the internal forces cancel ... also valid for all aspects of grinding. Coated mill internals represent the lowest

Cement grinding Vertical roller mills versus ball mills ... 80 years it was the predominant mill for grinding of raw materials and coal, ... and mill feed rate.

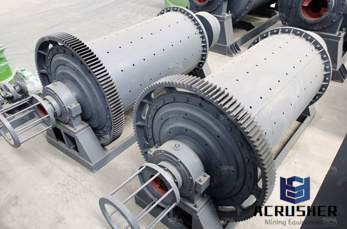

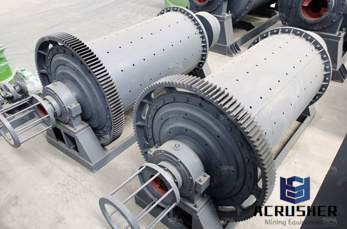

Mill Internal Wear Rate When Using Grinding Aid . wear metal from raw mill grinding process, Chryso Raw Mill Grinding Aid cement mill grinding .

Open Circuit Configuration ... to the IsaMill™ retains all media inside the mill and negates the need to use screens and ... very low wear rates, ...

Fosroc Grinding Aids Performance Enhancers CEMAX Technology. ... Special additives like Raw mill and Coal mill grinding aids BENEFITS OF ... Reduced Equipment wear ...

WhatsApp)

WhatsApp)