WhatsApp)

WhatsApp)

Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction and Mill Speed Critical Speed needs.

SBB''s steel glossary is great for finding the definition for any steel term associated to the industry.

2 METHODOLOGY A typical methodology for capacity enhancement and energy conservation would include: • Comprehensive study, covering the assessment of existing ...

Hardening. Hardening of steels done to increase the strength and wear resistance; Heated to 3050 C above the upper critical temperature and then quenched

82 ROOLVLRQ 5ROOLQJ ZLWK QLSSLQJ Figure Different types of grinding action by the grinding media. 7XPQEOL J 6KRXOGHU RI WKH ORDG *UDYLWDWLRQDO IRUFH )

High Shear Mixing In Paint Making by Christine Angos, Application Engineer, Charles Ross Son Co. Paints and coatings as we know them today have come a long way

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

Our portable threeaxis milling machines are perfect for wherever equipment repair applications involve milling critical mounting surfaces.

1300B Tub Grinder. Our most popular tub grinder for use in industrial applications.

Features and Benefits Secondary Tertiary Crushers MP® Series Cone Crushers

Critical Parts. Made Locally. Supplied Globally. In need of a critical part for your product? Choose a part made in Jackson. Our strong community is made up of ...

Suranaree University of Technology JanMar 2007 Rolling of metals •Introduction/objectives •Rolling mills •Classification of rolling processes

An end mill is a type of milling cutter, a cutting tool used in industrial milling applications. It is distinguished from the drill bit in its application, geometry ...

Morbark MXG42 Stump Grinder is ideal for grinding smaller stumps. Compact size allows it to access sites not reachable with larger stump grinders.

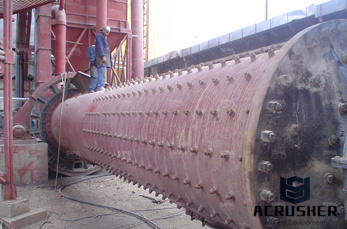

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory ...

2 HPGR High pressure grinding roll for the minerals industry Introduction During its relatively short history in minerals processing, HPGR technology

Basic information on wind energy and wind power technology, resources, and issues of concern.

Cement is a binding agent and is a key ingredient of the most used manmade material: concrete. The demand for cement is strongly correlated to the rate of economic ...

PILOT AND LABORATORY TEST PROCEDURES 1 Introduction The attractive feature of semiautogenous grinding mills is that they can be fed directly with coarse ROM (run of ...

Machining MACOR ® Machinable Glass Ceramic. MACOR ® machinable glassceramic possesses a unique microstructure, composed of small, interlocked platelike .

The method of mortar and pestle is the most widely used in the WestAfrican countryside. Before grinding, women usually soak the seeds, and then let them either sit ...

GE Power Conversion Motors Medium / High Voltage and High Speed 190 to 100,000 kW 250 to 134,000 HP

bread making. Highspeed machinery can now accomplish the kneading and ripening processes in a matter of seconds. For some time, bread was thought to be ...

A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell''s inside ...

WhatsApp)

WhatsApp)