WhatsApp)

WhatsApp)

Notes on Ball Mill Design Energy Required for Comminution. Feed material is assumed coarse hard rock. Feed Size and Product Size are 80% passing mesh sizes (micron)

How can you design of ball mill Answers. What is a ball mill and how does it function? Ball Mill is widely used in metal and nonmetal mines, building materials and ...

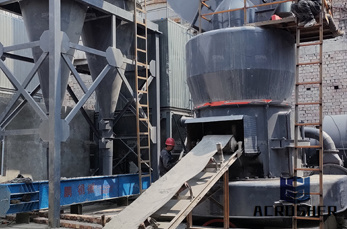

Autogenous mills, semiautogenous mills and ball mills for wet grinding. ... provide process engineering design layout, ... Ball mill in iron ore bene ...

ball mill design,ball mill manufacturer for sale in india . Highperformance systemsfor wet grinding applications. The comprehensive range of wet grinding systems ...

grinding mills. Grinding mills ... Service Department (CSD) has assisted with the inspection and maintenance ... The design features cast mill heads

· RecrystallizedRocket. Loading ... Ball Mill Critical Speed Working Principle Duration: 5:40. 911 Metallurgy Corp. 78,358 views. 5:40.

Ball Mill Design Pdf, Wholesale Various High Quality Ball Mill Design Pdf Products from Global Ball Mill Design Pdf Suppliers and Ball Mill Design Pdf Factory ...

British Rema have extensive expirence in the selection, design and sizing of Ball mills for a range of different applications. Learn more here.

What is a Ball Mill? A ball mill is a type of grinding mill, purposed similarly to the sag mill or other mining crushers. These machines are used to grind or mix ...

CHANGSHA TIANCHUANG POWDER TECHNOLOGY CO., LTD. is one of largest professional manufacturers in China engaging in design, manufacture, and sales of all .

The Selection and Design of Mill Liners . Malcolm Powell*, ... High–low double wave ball mill liners – These are a refinement of the wave liner, Figure 5.

Ball Mill Mechanical Design; Roasting Ball Mill Grinding; ... GNR Services provides precision kiln alignment services and sells Kiln OEM Parts Ball Mill Service and ...

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is ...

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

Intro: Make a Ball Mill in 5 Minutes. This is for all the pyro nuts that I came across on Instructables. This can be used to grind chemicals to a very fine grain or ...

TECHNICAL NOTES 8 GRINDING R. P. King. 82 ROOLVLRQ ... Additional power is required to keep the mill rotating. Power drawn by ball, semiautogenous and

Design and Optimization of Ball Mill for Clinker Grinding in Cement Plant ... quantify ball mill design parametersto reduce energy requirement for clinker grinding ...

ball mill service design ZCRUSHER. Ball Mill Design Highlights MIKRONS Ball Mill form a significant class of equipment used in the field of size reduction.

Hence a rod mill generally precedes a ball mill in a ... Mineral Processing Plant Design ... For more information on mill suppliers search for grinding mills in ...

Ballmill Design – Energy Required ... Ball Mill Design/Mineral Ball Mill/Grate Ball Mill ... we are always ready to offer you onestop service solution forBall Mill ...

Union Process has the experience and expertise to mill ... Choosing the Right Laboratory Ball Mills; Conventional Ball Mill ... Union Process provides Toll Milling ...

ball mill design/cement ball mill design/ball mill manufacturerMinggong Machinery. HOME; ... Our service engineer would be ready for service 24 hours per

ball mill design/cement ball mill design/ball mill manufacturerMinggong ... ABOUT US; NEWS; PRODUCT; CONTACT US; SERVICE; MORE About us. Shanghai Minggong .

Shop huge inventory of Ball Grinding Mill, Ball Mill Media, Ceramic Ball Mill and more in Metalworking End Mills on eBay. Find great deals and get free shipping.

WhatsApp)

WhatsApp)